BENEFITS & ADDED VALUES:

Return on invest with payback times ≤1 year

Process stabilization, downtime reduction and material approvals

Overall

guaranteed cost

savings/ reductions

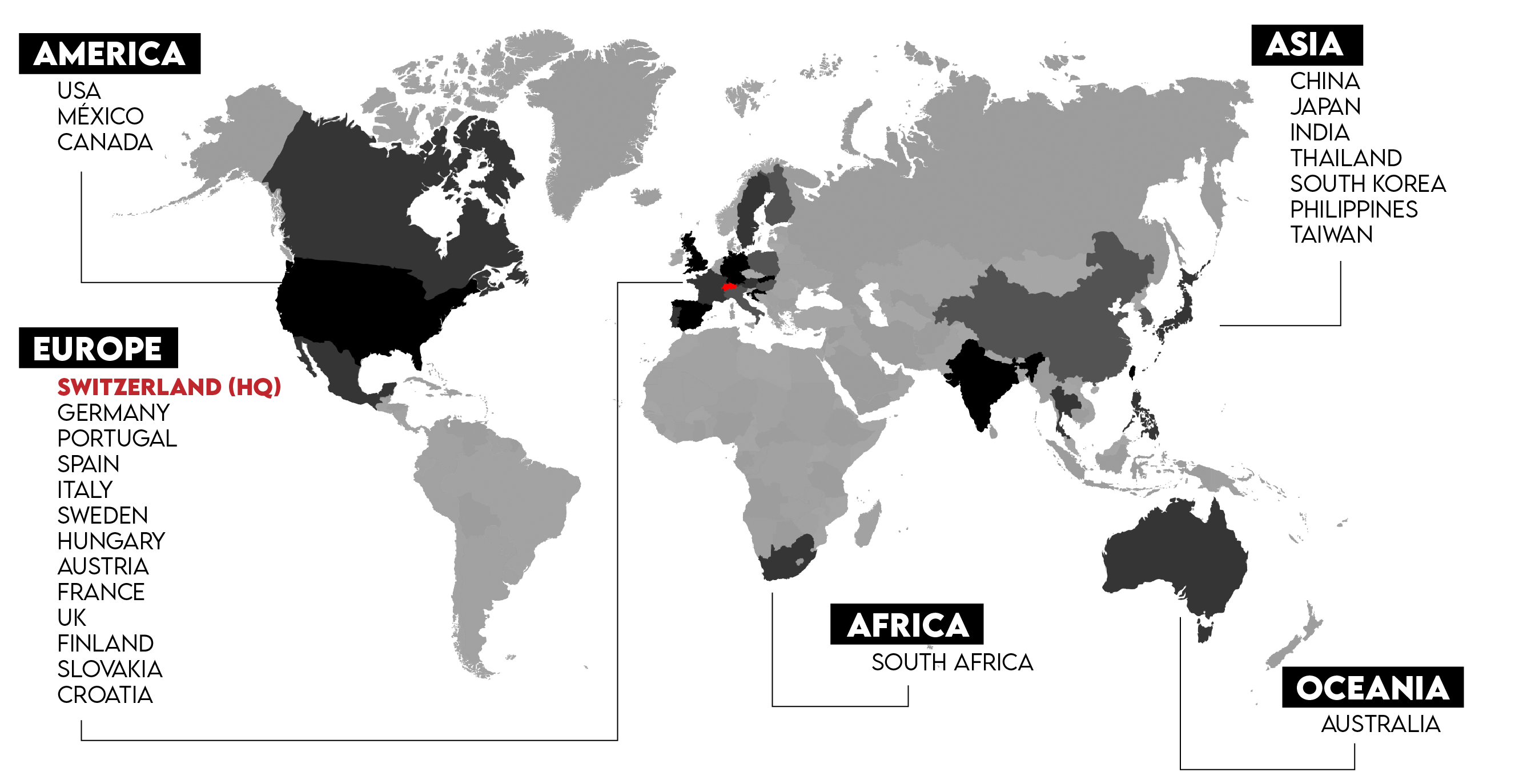

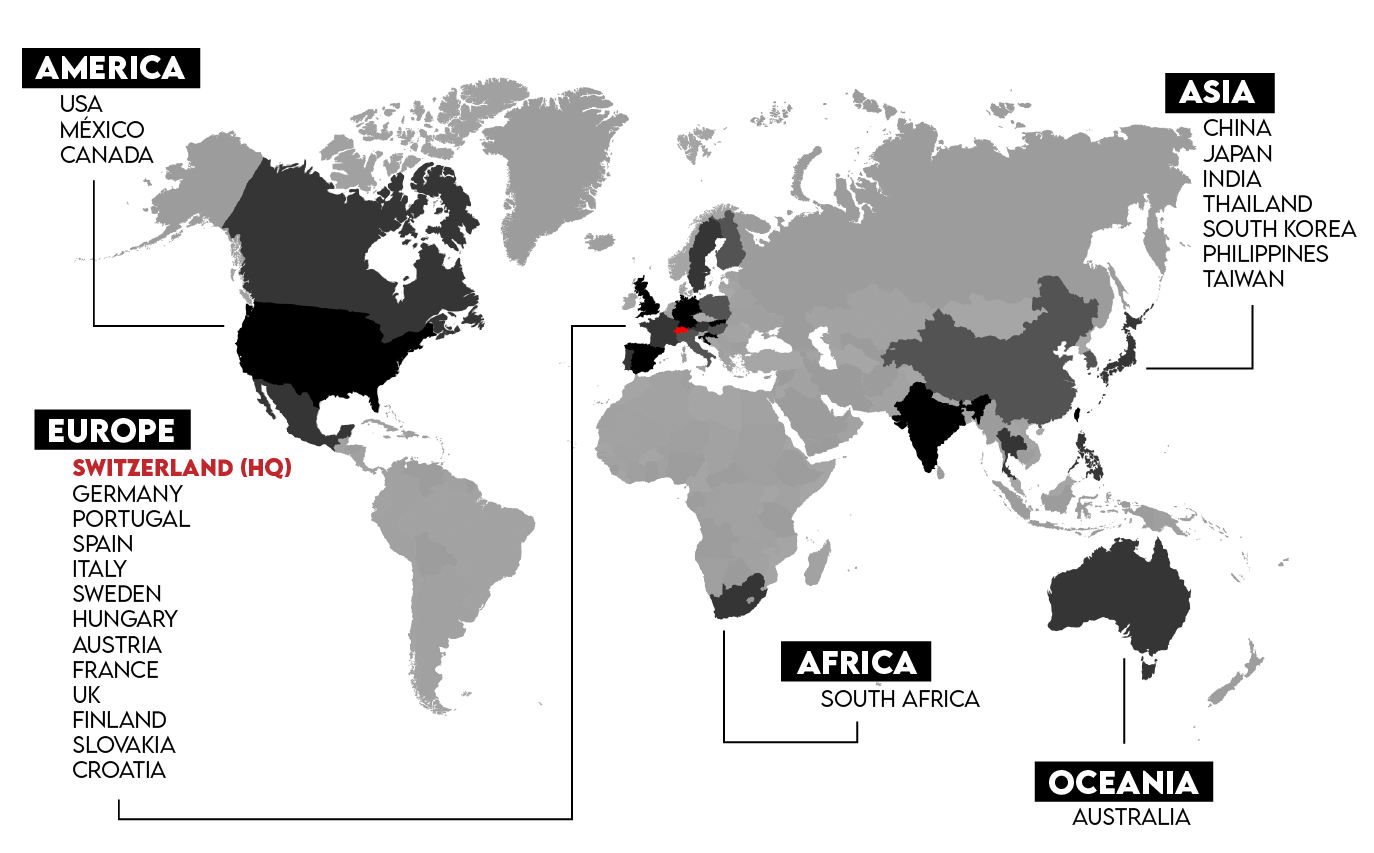

Global holistic market

know-how and

interface creation

Best balanced

engineering

(cost vs. function)

Serial and process development & on time releases

Ensuring OEM milestones & SOPs

Increase production performance

Customer

satisfaction

Environmental friendly, green economy